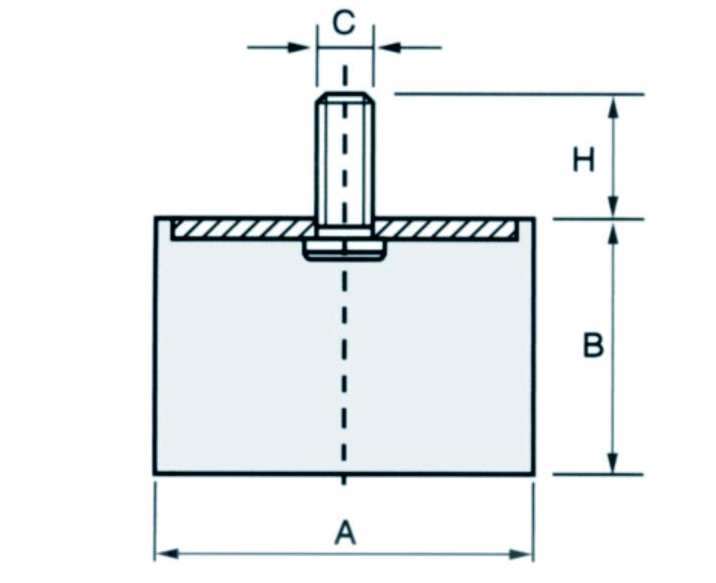

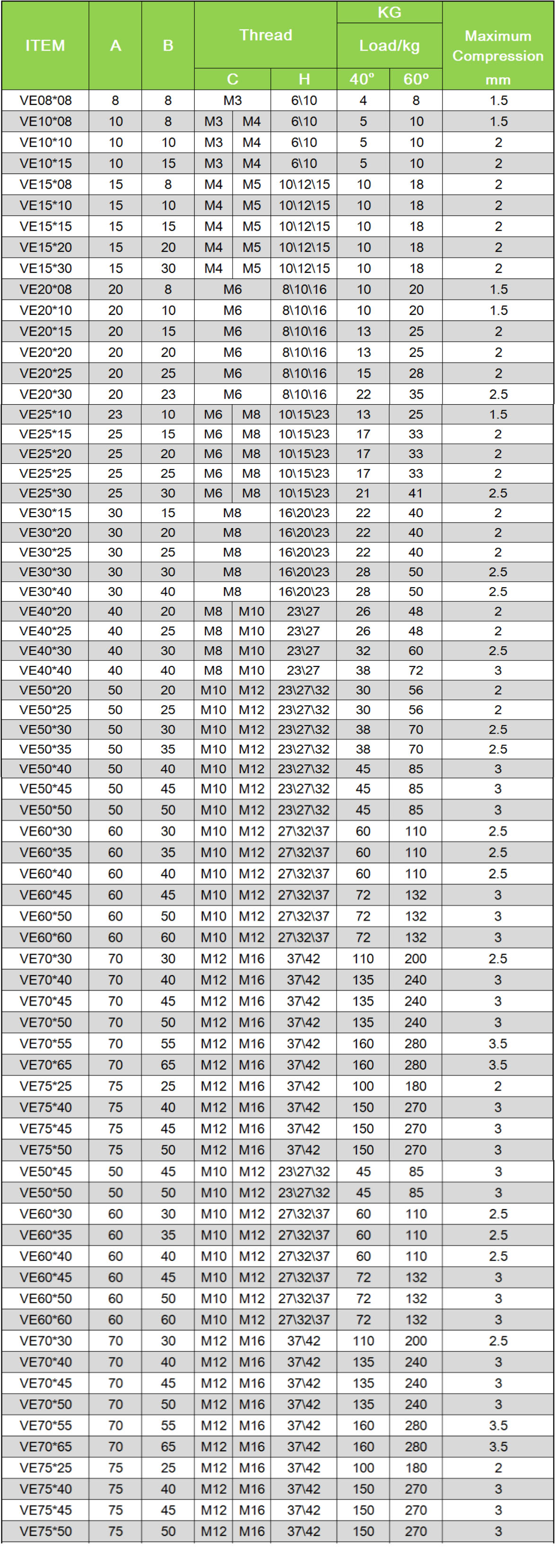

Cylindrical Mounts-Buffer Type VE Seires

- Product Detail

We proviced different type of elastomers upon different request.

Natural Rubber (NR)

Advantages: Outstanding resilience; high tensile strength; superior resistance to tear and abasion; excellent rebound elasticity (snap); good flexibility at low temperatures (-40° to 155° F).

Limitations: Poor resistance to heat, ozone, and sunlight; very little resistance to oil gasoline, and hydrocarbon solvents.

Operating temperatures should not exceed 155° F.

Natural Rubber is not recommended from exposure to oil, gasoline, ozone sunlight.

Neoprene (CR)

All static load test data for the Torsional Vibro-Insulator® Mounts is based on Neoprene.

Advantages: Good inherent flame resistance; moderate resistance to oil and gasoline; very good resistance to weather, ozone, and natural aging; good resistance to flex cracking; very good resistance to alkalis and acids.

Limitations: Poor to fair resistance aromatic and oxygenated solvents; limited flexibility at low temperatures (10° F to 180° F).

Nitrile (Buna-N)

Advantages: Very good resistance to oil and gasoline; superior resistance to petroleum-based hydraulic fluids; wide range of service temperatures (-65° F to 300° F); good resistance to hydrocarbon solvents; very good resistance to alkalis and acids.

Limitations: Inferior resistance to ozone, sunlight, and natural aging; poor resistance to oxygenated solvents.